How Predictive Analytics for Supply Chain Optimizes Operations

Supply chains are always operating in a state of uncertainty, whether it is a change in demand, a supplier glitch, or rising logistics costs. It is difficult to react quickly when relying on old reports or manual planning. This is where Predictive Analytics for Supply Chain comes into play.

By leveraging both past and current information, predictive analytics seeks to predict what is to come and inform better decisions. Instead of reacting to problems when they occur, companies can forecast demand, optimize inventory, and maximize efficiency before the fact.

Moving from traditional, reactive analytics to predictive, data-driven models helps organizations improve accuracy, reduce costs, and sustain service levels even in turbulent environments.

This shift from traditional supply chain analytics to predictive, data-driven models enables organizations to improve accuracy, reduce costs, and maintain service levels even in volatile conditions.

As digital transformation accelerates, predictive analytics in supply chain has become essential for building resilient and agile operations. AI development companies that adopt predictive approaches gain better visibility, faster response times, and a measurable competitive advantage across their supply chain.

Predictive analytics in supply chain involves the use of data, statistics, and machine learning algorithms to predict what will happen next in the supply chain. It is not only focused on what happened but on what is likely to happen next.

Traditional analytics in supply chain is all about analyzing history. It seeks answers to questions like:

On the other hand, Supply chain predictive analytics is all about looking ahead. It combines historical patterns with real-time data to predict what will happen next.

Using predictive analytics, businesses can:

This advanced analysis of supply chain data allows teams to respond before problems impact operations.

The ability to use data to make predictions and look ahead makes Predictive Analytics for Supply Chain a powerful tool that goes beyond simple reporting. It helps to eliminate uncertainty, improve efficiency, and make better decisions about planning and procurement.

Predictive Analytics for Supply Chain enables organizations to move from reactive problem-solving to proactive optimization. By forecasting future scenarios, businesses can plan more accurately, reduce costs, and improve overall efficiency across supply chain functions.

Predictive models analyze historical sales data, market trends, seasonality, and real-time demand signals to forecast future demand more accurately. This helps organizations align production and procurement with actual market needs.

Example: A manufacturer can predict demand surges during peak seasons and adjust production schedules in advance, avoiding last-minute capacity constraints or missed sales opportunities.

Using predictive supply chain analytics, businesses can determine optimal inventory levels across multiple locations. Predictive insights help balance service levels with carrying costs by identifying when and where stock will be needed.

Example: Retailers can automatically adjust reorder points based on predicted demand fluctuations, reducing overstock while preventing stockouts.

Predictive analytics improves logistics planning by forecasting delivery times, transportation risks, and route performance. This enables smarter analytics supply chain decisions and proactive delay management.

Example: Logistics teams can anticipate potential shipment delays caused by traffic patterns or weather conditions and reroute deliveries before service levels are impacted.

Predictive analytics helps assess supplier reliability by analyzing historical performance, lead times, and external risk factors. This supports more accurate supply chain analysis processes and early risk detection.

Example: Procurement teams can receive alerts about suppliers likely to miss delivery commitments, allowing them to secure alternative sourcing in advance.

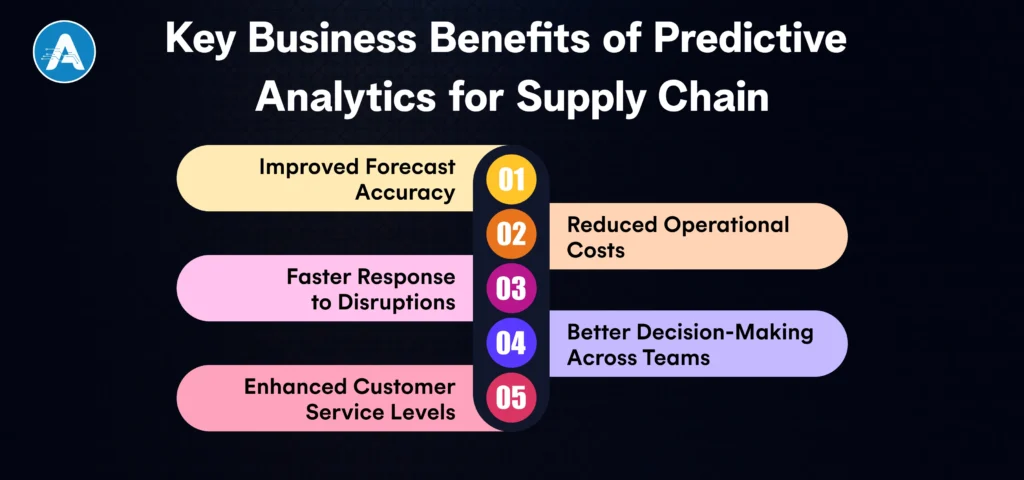

Implementing Predictive Analytics for Supply Chain delivers measurable improvements across cost, efficiency, and decision-making. Instead of relying on assumptions or static plans, organizations gain forward-looking insights that support smarter and faster actions.

Predictive models reduce guesswork by analyzing patterns in demand, seasonality, and external factors. This leads to more reliable forecasts and better alignment between supply and demand.

By optimizing inventory levels, transportation routes, and production planning, businesses can significantly lower holding costs, expedited shipping expenses, and resource waste.

With predictive insights, teams can identify potential risks, such as supplier delays or logistics bottlenecks, before they escalate. This allows proactive mitigation rather than reactive firefighting.

Shared insights from analytics in supply chain improve coordination across procurement, operations, and logistics.

Accurate demand planning and reliable delivery forecasts help ensure products are available when and where customers need them, improving satisfaction and trust.

The success of Predictive Analytics for Supply Chain depends on the right combination of technologies that enable accurate forecasting and real-time decision-making.

Key Technologies Used here:

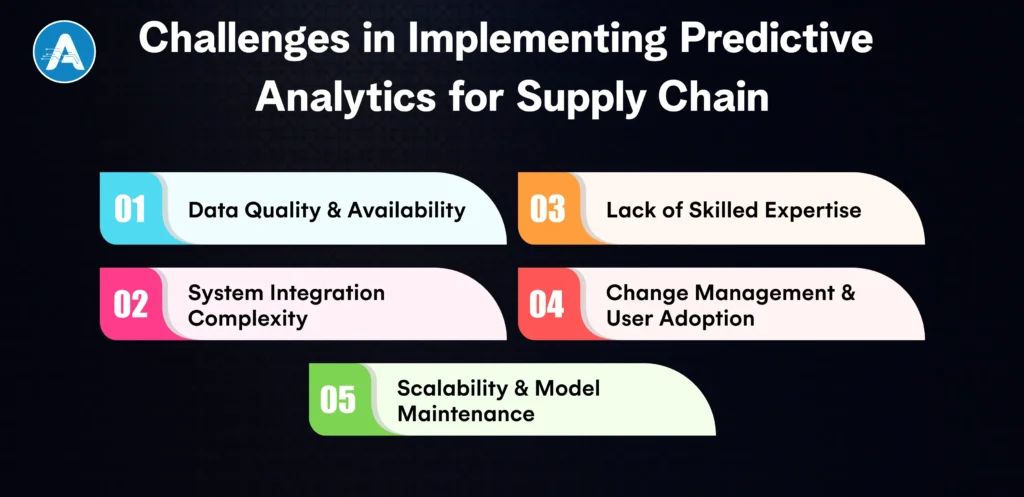

Although Predictive Analytics for Supply Chain presents considerable operational benefits, there are various challenges associated with its successful implementation. These issues should be addressed at an early stage in order to make perfect predictions and value in the long run.

Data quality is one of the largest issues with Predictive Analytics for Supply Chain. Supply chain data tends to be decentralized in several systems, including ERP, WMS, and TMS, and creates discrepancies and gaps.

Application of Predictive Analytics for supply chain necessitates smooth collaboration with the current supply chain systems. Predictive insights cannot be put to real-time use without appropriate integration.

Another major challenge in Predictive Analytics for Supply Chain is the shortage of skilled professionals who understand both analytics and supply chain operations.

Even with accurate insights, Predictive Analytics for Supply Chain may fail if teams do not trust or adopt predictive recommendations.

As supply chains evolve, Predictive Analytics for Supply Chain models must adapt to new data, suppliers, and market conditions.

By addressing these challenges with the right data strategy, technology foundation, and skilled resources, organizations can unlock the full potential of Predictive Analytics for Supply Chain and drive sustained operational excellence.

Predictive Analytics for Supply Chain is now an important organizational requirement that operates in a relatively dynamic and uncertain environment. With reactive changing to proactive analysis, companies can be able to predict demand precisely, manage inventory better, and be aware of the disruption well in advance of it impacting businesses.

Due to the fact that predictive models make use of real-time and past data, supply chain teams are more visible and in control of procurement, logistics, and distribution. This will result in reduced operation costs, enhanced service delivery, and speed. By working with the right AI application developers and adopting scalable AI application development services, businesses can overcome implementation challenges and maximize the long-term value of predictive analytics.

Get clarity on use cases, architecture, costs, and timelines with insights from 50+ real-world AI implementations.

Predictive Analytics to Supply Chain applies historical and real-time data, statistical and machine learning models in the prediction of future supply chain outcomes. It assists businesses to predict demand, manage inventory, minimize risk, and conduct proactive business decisions rather than responding to procurement errors through post-facto decision-making.

Conventional supply chain analytics is the one that looks at the previous performance and gives an explanation as to what has occurred. Conversely, predictive analytics in supply chain is prospective and involves looking into the future by forecasting what is expected to occur next using data patterns to plan and make decisions, and its implementation is faster.

The supply chain predictive analytics assists in solving some of the most widespread issues, such as poor demand forecasting, oversupply or undersupply of inventory, delays in logistics, or disruptive suppliers. Through a better analysis of supply chain data, the businesses will be able to cut the expenses and achieve a higher level of service.

The use of Predictive Analytics of Supply Chain demands artificial intelligence and machine learning models, big data and cloud analytics systems, and real-time data integration, as well as an advanced analytics dashboard. These predictive systems require the contribution of talented individuals, including an Artificial Intelligence Developer, to create and support them.

Yes. Whereas predictive analytics was previously only used in large businesses, nowadays cloud-based analytics supply chain solutions open up the technology to small and mid-sized businesses. Companies may begin with a few use cases, like demand forecasting or inventory optimization, and increase predictive capability as time goes on.

Continue exploring AI and technology insights

Design workflows are evolving at breakneck speed. AI Image Generators have officially transitioned from experimental “toys” to essential everyday assets for modern creatives. The…

Have you ever questioned yourself about how AI systems can make a decision that you can actually trust, such as warning about a fraudulent…

Many AI apps for iPhone are very good, but it’s more difficult to decide which ones are worth keeping. With hundreds of AI apps…